Call: 08071931145

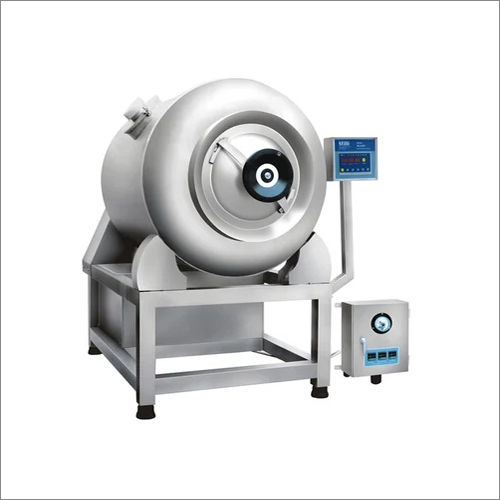

Tumbler Machine

MOQ : 1 Piece

Tumbler Machine Specification

- Voltage

- 220-240 V

- Material

- Stainless Steel

- Usage/Application

- Industrial, Mixing, Polishing, Surface Finishing

- Phase

- Single Phase

- Machine Type

- Tumbler Machine

- Frequency

- 50 Hz

- Automation Grade

- Semi-Automatic

Tumbler Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Tumbler Machine

A Tumbler Machine is a type of mechanical equipment used for polishing, deburring, and finishing small to medium-sized parts. The machine consists of a rotating barrel or drum that contains the parts to be finished along with abrasive media, water or other liquid, and sometimes finishing compounds. Tumbler Machine is popular for its ease of use, low maintenance, and relatively low cost compared to other finishing equipment. This is also versatile and can handle a wide range of part sizes and shapes.

Efficient Surface Finishing for Industry

Specially designed for industrial mixing and polishing, this tumbler machine harnesses semi-automatic technology for enhanced output. Its stainless steel body ensures durability and easy maintenance, while the single-phase operation streamlines integration into existing workflows.

Versatile Application Across Sectors

Perfect for metalworking, jewelry making, automotive, and manufacturing sectors, the tumbler machine delivers precise surface finishing and cleaning. The machine suits varied industrial needs, offering flexibility for both small and bulk processing tasks.

FAQs of Tumbler Machine:

Q: How does the tumbler machine enhance surface finishing in industrial applications?

A: The tumbler machine utilizes rotational movement to uniformly polish and clean items, resulting in smoother surfaces, improved shine, and consistent finishing across batches. Its semi-automatic function streamlines repetitive processes for increased efficiency.Q: What materials can be processed using the stainless steel tumbler machine?

A: This tumbler machine is engineered to handle a range of materials including metals, plastics, and ceramics, commonly used for polishing, deburring, and surface finishing tasks in varied industrial settings.Q: When should a semi-automatic tumbler machine be used over a fully manual option?

A: A semi-automatic tumbler machine is preferable when processing larger volumes or when consistent and high-quality finishing is required. It reduces labor input and minimizes variability compared to manual methods.Q: Where can the tumbler machine be installed for optimal performance?

A: The tumbler machine is suitable for installation in factories, workshops, and production plants throughout India, requiring only a single-phase 220-240 V power supply to operate efficiently.Q: What is the typical process for mixing and polishing using this machine?

A: The process involves loading the items and polishing media into the drum, setting the desired parameters, and activating the machine. The tumbler then agitates the contents, achieving uniform mixing and polishing by rotational movement.Q: What are the usage benefits for distributors and wholesalers in India?

A: Distributors and wholesalers benefit from offering a reliable, versatile machine that meets industrial standards, ensuring customer satisfaction and repeat business. The stainless-steel construction and efficient power usage also reduce maintenance costs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry